In this article, we will learn about Chain Drives: Types of Chain Drives, Advantages, Disadvantages, and Application

A chain drive is a Mechanically operating system where we used different types of chains to transmit the power or for the movement of some things.

Generally, a chain drive is used where the distance between the power produced and where it is to be transferred is less, however, this is not applicable for all. In some cases, we can use a chain drive for longer distances power transfer.

In belt or rope drive we see there is some percent of slip occurs, but in the chain, there will be no slip. But this does not mean that 100% power is transmitted from one another device due to friction loss some amount of power loss we can generally see.

In chain drive, the speed ratio remains constant which is a major advantage of chain drive and here there is no slippage and in the case of belt drive, there is slippage so the speed ratio changes as per slippage.

A chain is made by a number of links and those are connected with the help of a pin.

Chains are run over a wheel named sprocket which has several amounts of teeth around the circumference of that to grip the chain, however, not all the chains need that sprocket to run over. We will further see the different types of chains and where we used that below in this article.

Types of Chains:

In the field of Mechanical Engineering chains drive can be classified into three broad categories and those are:

- Hoisting Chains

- Conveyor Chains

- Power transmission Chains.

So let’s start the discussion from the Hoisting Chains.

Also Read: Steam Condenser: Types, Working Principle and Operation, Advantage, Disadvantage and Application

Hoisting Chains:

Let me tell you what is hoist? A hoist is a mechanical device that is used to lift a load or lowering a load, it can be used for shifting some heavy product from one place to another place in a workstation.

The chains used in this type of devices is named hoist chain, these chains are quite strong to handle heavyweight.

Hoist chains can be classified into two categories:

- Oval-Link Chains.

- Stud-Link Chains.

Oval-Link Chains:

It is one of the common types of chain used in hoists, it consists of many oval links attached to each other. These types of chains are also called Coil Chains. Links to this type of chain are oval.

However, there are square link types of chains that are also available., but the kinking is occurred easily due to high loading.

Generally, we used these types of chains at low speeds only.

Stud-Link Chains:

The stud-link chains are used to minimize the deformation and link or tangle easily.

In this type of chain, a round bar or stud is used to fit inside the oval-link chains to provide more strength to the chain.

It is used in Ship to up and down the anchor of the ships, and some crane hoist where we need to lift a very high amount of load.

Conveyor Chains:

As the name suggests conveyor chains, means these types of chains are mostly used in the conveyor. If you don’t know the conveyor, it is a mechanical device system that is used to move the materials from one place to another.

This type of chain is well shaped that it can easily run over the sprocket.

Generally, this type of chain is made of malleable cast iron and used in Low-Speed Machinery approx 2 m/s.

The one major disadvantage of this type of chain is the motion of the chain is not smooth, there are chances of wear and tear out.

Conveyor Chains are categorized into three types:

- Detachable or Hook Joint types Conveyor chain.

- Closed-end pintle type conveyor chain.

Detachable or Hook Joint types Conveyor chain:

Detachable or Hook Joint types Conveyor chains are used in a conveyor where the length between power transmission is short.

Closed-end pintle type conveyor chain:

This type of chain is consists of a barrel and link and made in a single casting, then the chain is heat-treated to provide higher strength.

Power Transmission Chains:

- You can easily find out by name of the chain that it is used to transmit the power.

- This type of chain is made of steel and sometimes it heats treated to minimize wear and tear.

- This type of chain has greater accuracy and can easily run over the sprocket.

Power Transmission Chains are categorized into three types:

- BlockChain

- Roller Chain

- Silent Chain or Inverted tooth Chain

BlockChain:

This type of chain is used in low-speed areas and will produce noise due to the sudden contact between sprocket and chain, however, this is used in some low-speed conveyor machines.

Roller Chain:

This type of chain is constructed by:

- A bush

- Inner Link

- A pin

- Outer Plate

- Inner plate

- Rollers

In this type of chain, a bush along with the roller is fitted inside both the plates then a pin is passed through both the end of the roller to fasten it.

The rollers are free to rotate inside the bush so that when it contacts between the sprocket the wear tear would be minimized.

Generally, it is made of steel.

It is soundless and wears less as compared to the blockchains and used in any circumstances and this type of chain gave much service area if proper lubrication is maintained.

Chain Drives: Types, Application, Advantages, and Disadvantages

A chain drive is a Mechanically operating system where we used different types of chains to transmit the power or for the movement of some things.

Generally, a chain drive is used where the distance between the power produced and where it to be transferred is less, however, this is not applicable for all. In some cases, we can use a chain drive for longer distances power transfer.

In belt or rope drive we see there is some percent of slip occurs, but in the chain, there will be no slip. But this does not mean that 100% power is transmitted from one to device due to friction loss some amount of power loss we can generally see.

In chain drive, the speed ratio remains constant which is a major advantage of chain drive and here there is no slippage and in the case of belt drive, there is slippage so the speed ratio changes as per slippage.

A chain is made by a number of links and those are connected with the help of a pin.

Chains are run over a wheel named sprocket which has several amounts of teeth around the circumference of that to grip the chain, however, not all the chains need that sprocket to run over. We will further see the different types of chains and where we used that below in this article.

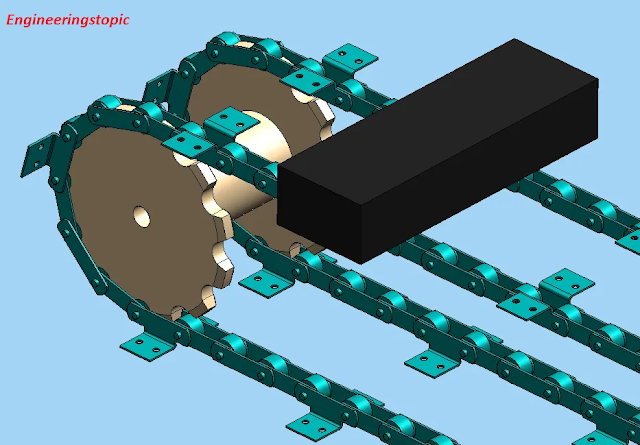

chain drive

- A sprocket with a roller chain

Types of Chains:

In the field of Mechanical Engineering chains drive can be classified into three broad categories and those are:

- Hoisting Chains

- Conveyor Chains

- Power transmission Chains.

So let’s start the discussion from the Hoisting Chains.

Hoisting Chains:

Let me tell you what is hoist? A hoist is a mechanical device that is used to lift a load or lowering a load, it can be used for shifting of some heavy product from one place to another place in a workstation.

The chains used in this type of devices is named hoist chain, these chains are quite strong to handle heavyweight.xz

Post a Comment